The Juneau Empire decided to launch a Travel section in the paper and asked for submissions. Some people need only be asked once:

You are not logged in.

Log in

|

Alaska Wittig Family Blog

Friday, July 27, 2007

Another Newpaper Article

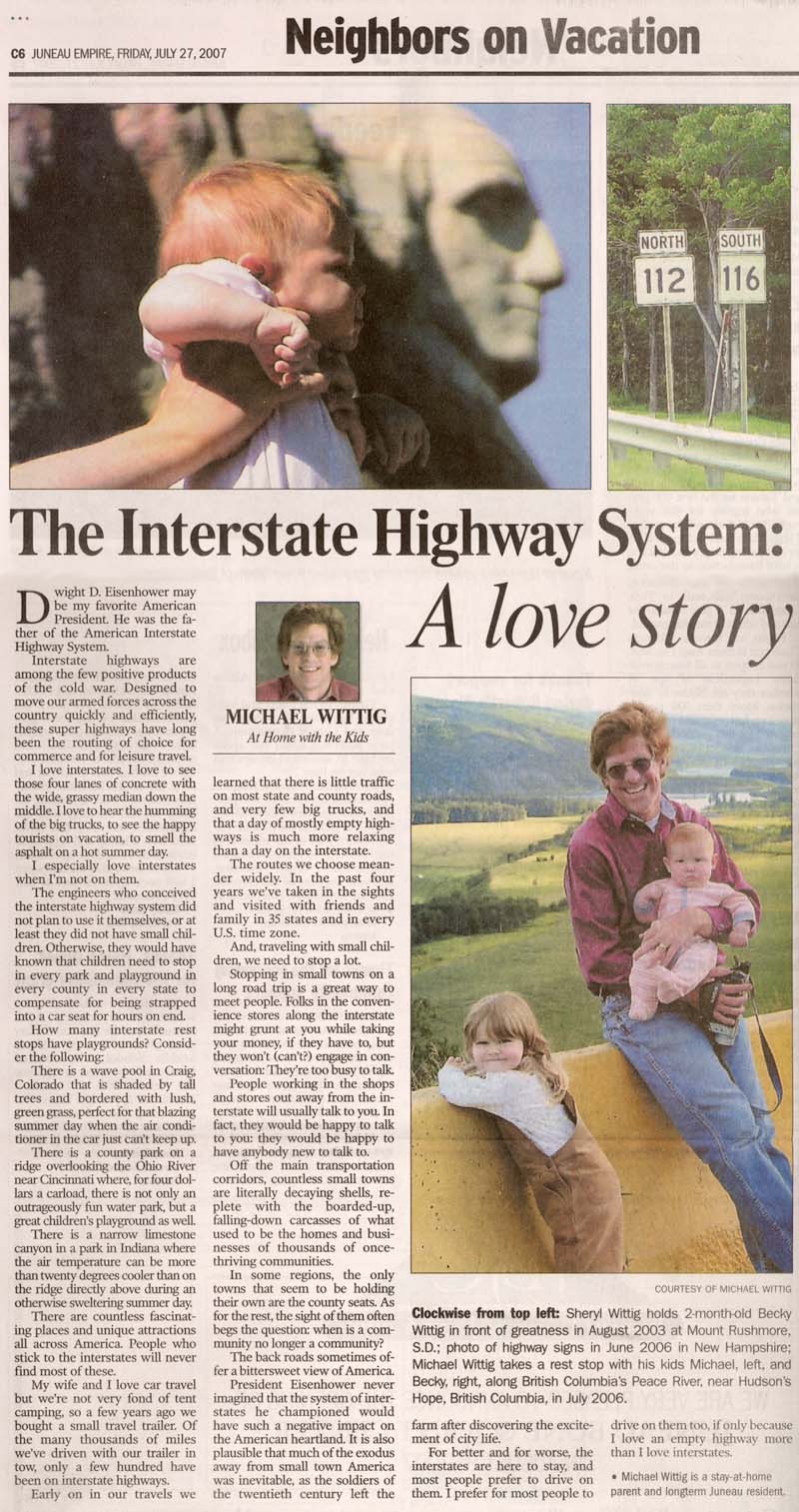

The Juneau Empire decided to launch a Travel section in the paper and asked for submissions. Some people need only be asked once:

Posted

at 7:54 AM YDT

Wednesday, July 18, 2007

Third Wednesday of the Month

Another month, another column. Gee, it's almost like having a job! Sheryl and I were pleased to see the plug for the column on the banner on page one.

Posted

at 8:14 AM YDT

Monday, July 9, 2007

Out in the Woodshed

We left off just before the much anticipated opening of Home Depot. We went, we saw, we spent $2.36 for a bathtub drain stopper. I did not buy any heater stuff. In truth, while the prices on some items are slightly below our other retailers, the new store hasn't got a monopoly on quality, selection, qualified assistance, or price. One of the things we investigated at Home Depot was our replacement heating system for the house. Despite the fact that Home Depot is the distributor for Trane [heating and air conditioning] products, they apparently believe that people in Alaska don't need central heat, because there weren't any central heating units available in the store, and they have no plans to have a Trane representative in their store. They did have some built-in electric heaters that caught my attention. I went home and ran some calculations, then went on the internet and found a host of products (most of which are not carried by Home Depot) that will probably suit our needs. The heaters we're currently investigating are relatively small and easy to install (they are designed to go into a wall cavity and look just like a heater vent). Individually, these heaters are capable of warming small areas, but several of them will heat the whole house. There are several advantages in using these small electric heaters. For one thing, we can add heat to the areas of the house we're using and let the vacant areas be a little cooler. There is the redundancy factor of having several heaters, which means being able to keep the house warm even if one of the units quits working for whatever reason. There is also a potential for some energy savings versus the hot water baseboard heat, because we won't have any heat loss in the 120' of piping that connects the baseboards in the otherwise unheated crawlspace. Lastly, putting these heaters in does not rule out an additional heat source (such as the heat pump) at a later date if the economics justify it. But we don't need very much heat in the house in July, so it is time to visit the other home improvement projects on the docket. Home Depot has a decent selection of lumber, but it is not the widest selection in town, and it isn't even the best price (unless you count their guarantee to undercut the competition by 10% if confronted by lower prices). We wanted a woodshed in which to dry our firewood. While we were at it, we wanted a storage/work area for gardening projects and yard tools. I drew up a set of plans, came up with a list of materials, and went on a little tour. When I discovered that the cost was essentially the same between Home Depot and Don Abel, I went with the local outfit. So here are a few pictures of the project. I realized almost immediately that moving a large quantity of lumber any distance is much easier with a set of wheels, and it so happened that we had a set of wheels on hand, which really made the moving easy. There were no glitches in the construction, but there were some design changes as I went along. The sheathing, for instance, was originally intended to be mounted on the outside of the posts, but I liked the look of the posts so much that I didn't want to hide them behind a monolithic wall, so the sheathing wound up behind the posts. The 2x4's placed on edge for wood storage were in the original plan (to keep the wood off the floor and ventilated), but the additional planks in between weren't contemplated until later, and weren't installed until after I inadvertently stepped in-between the edge-placed planks (looking up when I should have been looking down). There is still more to do. A wall belongs between the wood storage area and the rest of the shed. We are still discussing how we want to use the work area, so we haven't decided for sure what kind of shelving and/or counter space we want to put in. We also want a ramp to get from the shed to the yard, assuming we store our lawnmower in the new space. At any rate, the bulk of the work is complete, or at least far enough along to send out these pictures.

Ah, the joys of summer.

Posted

at 9:47 AM YDT

Updated: Monday, July 9, 2007 9:57 AM YDT

Thursday, June 28, 2007

A New Home Depot!

Our new Home Depot opens today. Of course, our week of appliances was last week, but we’ve still got some things to shop for. As it turns out, hardware for a radiant floor heat system will not be on the list. After months of calculations and estimations, I [Michael] have determined that our subfloor assembly is too thick to put tubing under it and get enough heat through it, given the numbers we came up with on energy usage last winter. It’s really, really hard to find any solid information regarding heat transfer in radiant systems, and even people trained and qualified to do these kinds of calculations failed to pick up on our floor construction. After quite a lot of searching on the internet I found a couple of mathematical formulas pertaining to heat flow through a wall, and after experimenting with a set of hypothetical numbers (hypothetical because solid information is lacking) it became obvious that our floor was, at best, only marginally suitable for a radiant floor application. We could still get some heat through the floor, and it would be comfortable, but I don’t think enough heat would make it through in sub-zero weather, and because of the lag-time the system would really only work if kept on a “slow bake” setting, with some form of additional heat going into the house for cold weather or quicker warming times. Unfortunately, the cost of the radiant installation is such that I can’t justify it without knowing it could handle all of our heating loads. Of course, I may be wrong about this too. I am using the heat loss numbers derived from our oil consumption last winter. Last winter (and now), we had no insulation under the floor, and there is no vapor/infiltration barrier in the attic either. By this winter we hope to have both of these situations remedied. We are also now heating our domestic water seperately from our space heat. In short, I expect the heating requirements of our house to be considerably less than the numbers I am compelled to use in my calculations. Considerably less, yes, but how much less? That's the uncertainty. New plans: Insulate the floor (without installing radiant heat: we can do this in a way that allows us to add the system later if we decide it's viable). Add a vapor barrier to the attic (easier than might be thought actually, since it involves little more than pulling the old fiberglass out, spraying in an inch of foam on top of the sheet rock, and putting the fiberglass back in: the foam provides the barrier). Fabricate a new heating system. That last part of the plan is the most interesting. I kept most of the hardware from the old oil heater. For very little additional money I can fabricate an electric heater with enough juice to handle our worst case scenario (twenty-five below is the temperature I'm designing for). Oddly, I haven't found any electric water-heating equipment designed for my load and flow rates, but I'm still shopping, and if I don't find something to buy I guess I'll put my Industrial Mechanics degree to work again. Considering that the whole heat system is still undecided I am leaning toward the fabrication idea, because the cost will be slight and I won't feel committed to it as I would be if I spent money for a store-bought solution. Whether we buy or build our next heater, I plan to meter it so I can monitor its energy usage, and perhaps the numbers from next winter will point the way toward our ultimate heat solution. And now... off to Home Depot!

Posted

at 8:58 AM YDT

Wednesday, June 27, 2007

Video Problem

There was a problem with the video yesterday. It didn't work for PC users (most of the world)! It should work better now for anybody who wants to try it, and let us know if there are any other problems.

Posted

at 3:27 PM YDT

|

||||||||||||||||||||||||||||||||||||||||||||||||||||